Tag Archives: media reactor

Two Little Fishies 150 PhosBan Reactor Product Review

This is among the more popular fluidized reactors in use today due to its smaller size, affordable pricing, and flexibility of use. The below information was taken directly from the manufacture’s website

http://www.twolittlefishies.com/documents/1202405781.pdf

PhosBan Reactor 150™

The PhosBan Reactor 150 is designed with the upflow principle to achieve the most efficient use of PhosBan® or other chemical filter media. By pushing water from the bottom upward through a dispersion plate, it forces an even distribution of water through the media, and prevents channeling. It can be mounted hanging on the back of the aquarium or below the aquarium. Hose barb connections are for 1/2 inch i.d. tubing. Includes 1/2 inch barbed ball valve for flow control, and hose clamps. Use with any pump having a capacity between 100 and 250 gph, but regulate the flow rate to the recommended 20 to 30 gallons per hour with the included ball valve.

I have been using one for a few months now and have found it to be very good value for the money.I am currently using mine for biopellets on a sumped 120 gallon FOWLR aquarium. I have friends and fellow hobbyists who swear by this reactor and have been using it for a few years with phosphate removing media.I really like using this reactor in a sump due to the small footprint it takes up and the fact I will not have to worry about it leaking when used in a sump. The below is a list of pros and cons that I have found using this reactor.

Pros:

-Small size can be used in all most any type of sumped set-up with minimal room lost.

-Can easily fit under aquarium stand if not used in a sump

-Can be used in a hang on back style set-up

-Comes with a built in ball valve

-Very reasonably priced

Cons:

-The supplied connectors often leak a very small amount.If used outside a sump or aquarium, you will need to add better clamps to connect the fittings and hose together in order to prevent any leaks

-You will still need to purchase a pump to use it in some configurations.

-It is not convenient to remove and take apart for routine cleaning or replacing media.

-Some types of media can clump up or just not move around the outside edges along the bottom of the reactor.However, this is a common situation to find in all reactors with a similar design.

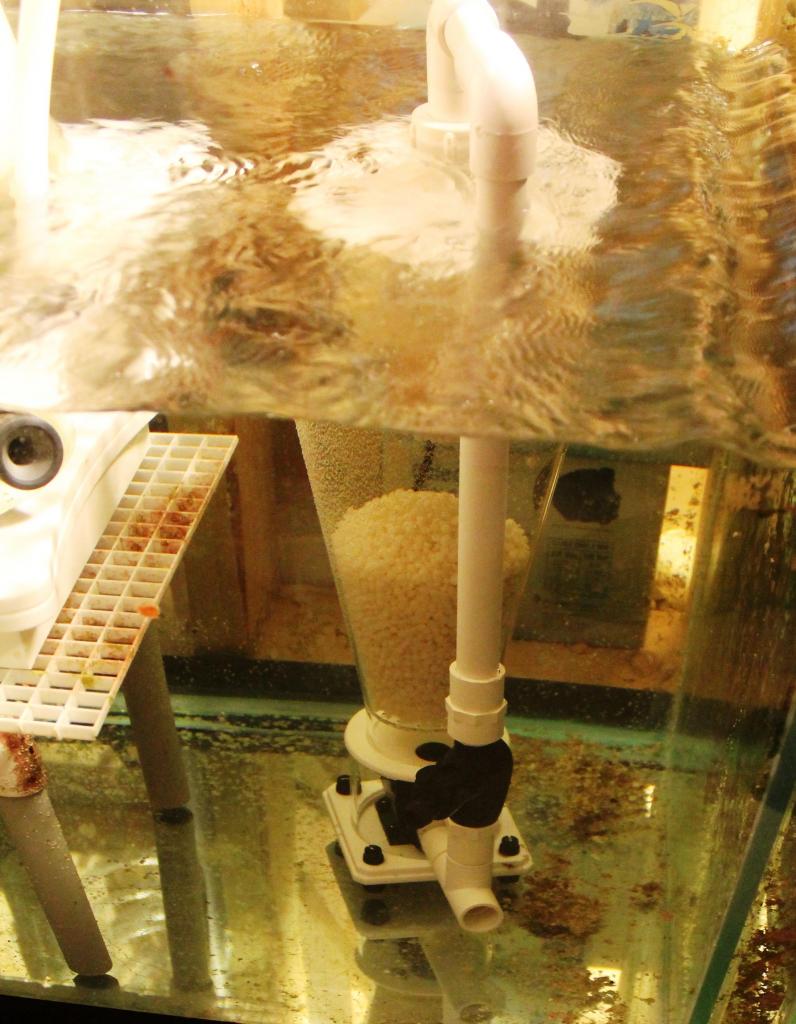

One quick tip on using this in a sump, if you keep the portion of the reactor with the media in it below the water line in the sump, you will need lover flow rates through the media and the reactor will work better. I took a picture and inserted it below to help explain what I am talking about.

Overall I am happy with the performance of this reactor and would recommend it to anyone who has a set-up with limited space for a reactor.

CAD Lights Biopellet Reactor Equipement Review

For the past few years I have been using biopellets in a traditional or common media reactor. While this traditional design has been a highly effective design for media such as phosphate removers or carbon, I have found it not to work that well when with the biopellets on the market today. In my experience, it has been challenging to maintain the biopellets properly suspended in the reactor with the correct amount of flow. Clumping and uneven biopellet movement due to uneven water flow through the reactor has always remained a challenge.

I had been looking for an alternative to the common media reactors. In early 2012, Cad Lights Aquariums launch the Conic Media Reactor (CAD Lights Biopellet Reactor), which is a new reactor designed specifically for use with biopellets. The model I purchased is the BR-1

The below information is taken directly from the manufacture’s website

http://www.cadlights.com/index.php?main_page=product_info&cPath=51&products_id=213

“Specifications

* NEW 3-way recirculating valve gives you the control of the Bio-reactor at your hands.

* Total space useage: 6″ x 6″ x 12″ (16″ high with plumbing)

* Capacity of 50G up to 350G

* Can hold up to 750ML of Bio-pellets.

* Compatibility: works best with Tapered edge or other non-perfectly round bio-pellets.

* Built in pump

* 11.5W of energy use.

* Standard 1/2″ SCH40 PVC can easily be extended to reach into other chambers for installation.

* Total silence.”

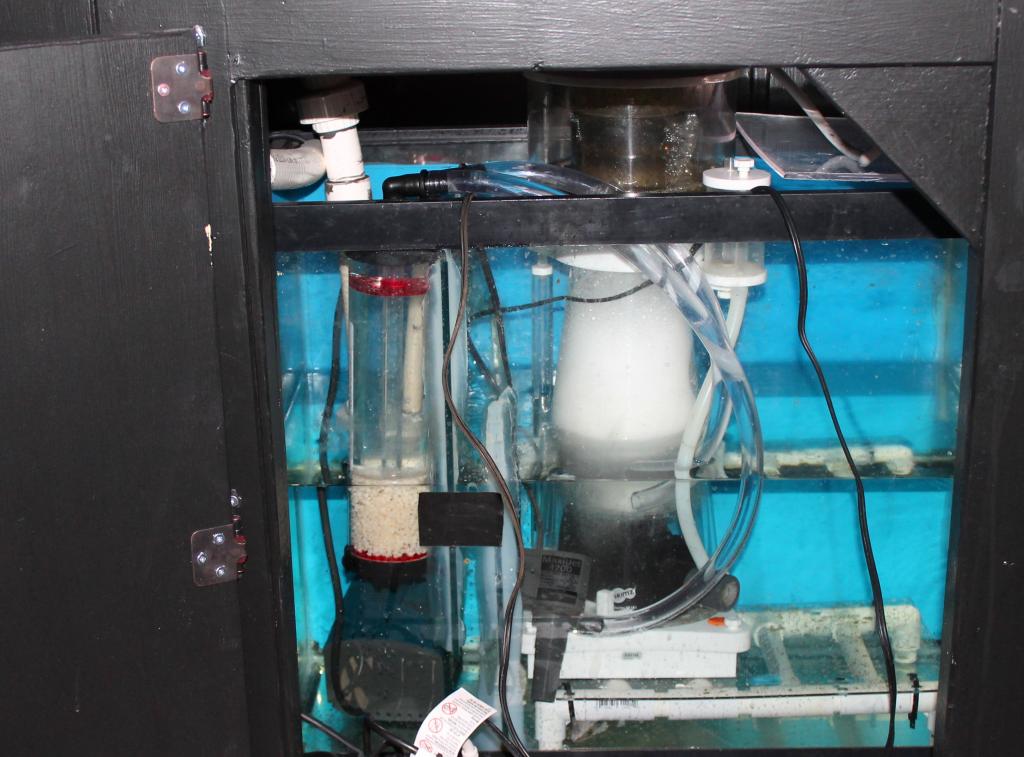

Base on my own experience, this design has two main features that make it different

1 The media chamber is an inverted triangle shape.

2 The pump is placed inside the reactor beneath the reactor chamber.

These two new features help to focus the right amount of flow even through the pellets keeping all pellets consistently moving within the reactor chamber while keeping the foot print of the reactor smaller. Based on a few weeks of use, I am extremely happy with the performance of this reactor. In my opinion, this design makes the Cad Lights Conic Media Reactor among the better reactors on the market right now.

I was also extremely impresses with the manufacture. The reactor cam very well packaged and they even went the extra mile to pre-wrap the threaded connection on the one fitting you have to screw onto the top of the with a good quality thread tap. This shows the company cares about quality.

The only drawback that I can see with this reactor design is that it does require more height clearance than a traditional media reactor which could be a limiting factor when using in an aquarium stand on aquariums smaller than 150 gallons.

Although I feel this reactor doesn’t work as well as the manufacture claims, it still is a very good quality reactor and I would recommended it to anyone who has the required room in their sump for it.