Category Archives: Equipment

Aquarium Plumbing Valves

I have received a lot of questions about using valves on aquarium set-ups. This article is meant to provide a little more detailed information to supplement the already posted Aquarium Plumbing Article here for those people who would like more detailed information on the commonly used valves on sumped marine aquariums.

https://www.reefaquarium.com/2012/aquarium-plumbing-basics/

There are many different types of valves used in the hobby today.In the article I am only covering the most common types of products used. All the information listed below is some accurate but you should assume there are many different variables can effect product performance making it very hard to develop a hard fast rule that applies in very situation. Use the below as guidelines. In additional, products made outside North America not have been manufactured up to ASTM, (American Society for Testing and Materials)or CSA (Canadian Standards Association) standards making those product specifications hard to determine.That is why I always prefer to ensure the plumbing products that I purchase are manufactured to either ASTM or CSA standards to ensure the specifications will be consistent.

Please keep in mind, there are seemingly hundreds of different types of plumbing companies but it is important that you choose one of the best plumbing companies who has the right knowledge.The valves that I am referring to in this article are the ones that I have come across that can be made with materials that are aquarium safe and are also suited for the typical sumped aquarium set-up.

Regular Valves

I would refer to any valve that is used to regulate or completely shut off (stop) flow as a regular valve.The below valves are the most common valves that I have found in the hobby so far.

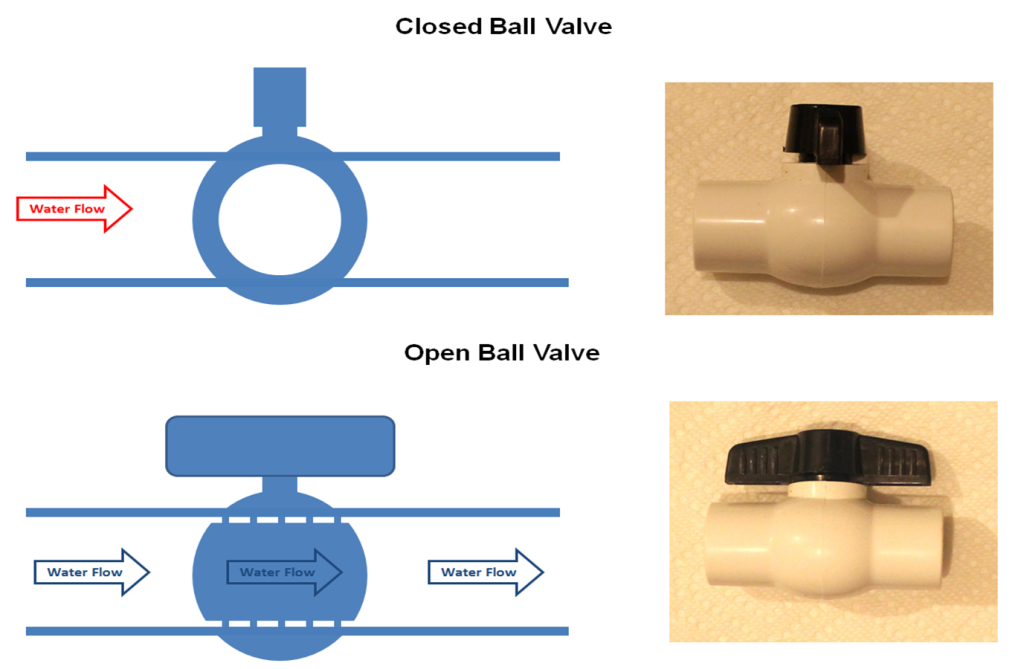

Ball Valves

These are about the most common style of valve that you will find in use in the aquarium hobby.They are very easy to find in most hardware and plumbing supply stores in models that are made with materials that are safe for aquarium use.The models that are made of PVC material range in size for ½ to 6 inches.You can get them in SCH 40 and SCH 80 PVC which will have the same tolerances and specifications as the same PVC pipe and fittings. Ball valves are also available in screwed or socket weld (glued) connections depending on how you want to connect this valve into your system.This is my preferred valve to use in any type of plumbing set-up.The reason for this is that ball valves will restrict the flow going through the valve the least of any type and they are also the least likely to fail or leak.The only drawback to using these valves in PVC is that they are not the best suited for high pressure and high heat unless you have a ball valve made of PVC SCH 80.

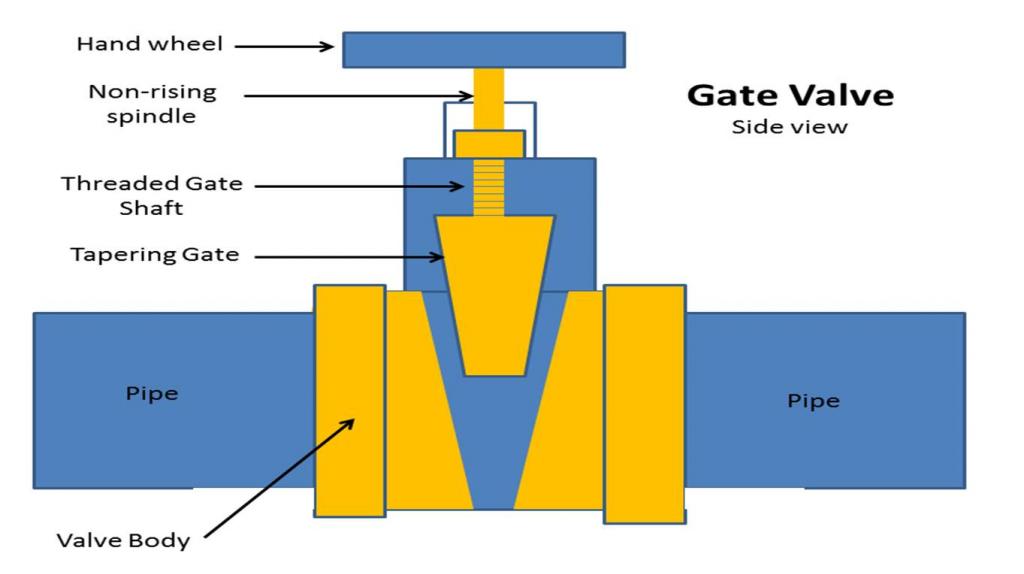

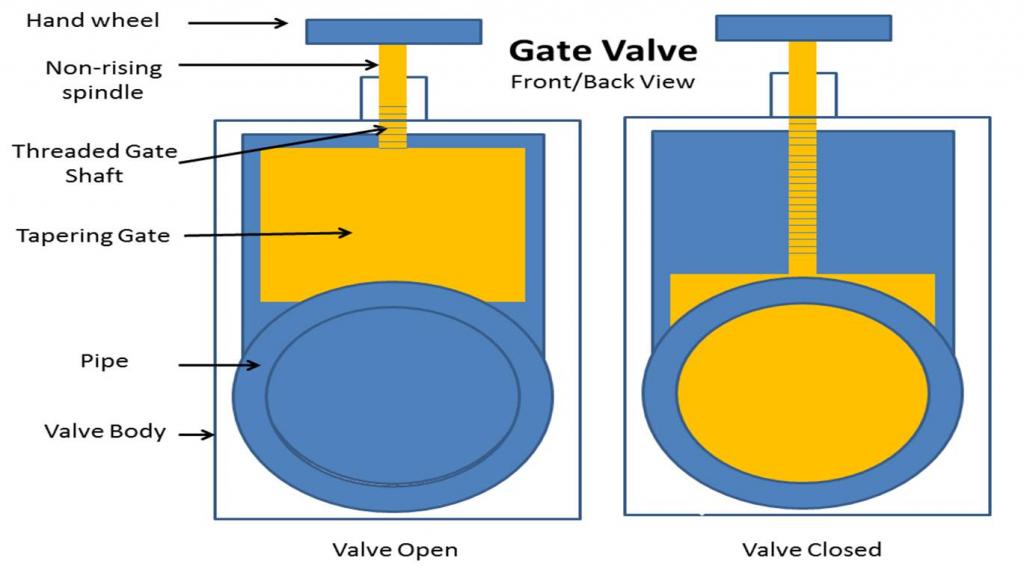

Gate Valves

These valves are somewhat common to find in the hobby.They will reduce the flow going through them more than compared to a ball valve. Gate valves made in PVC are harder to find, mostly being found in plumbing supply stores or some on-line aquarium supply stores. The can also com in PVC SHC 40 and PVC SCH 80 material but are more common to find in SCH 80 as the valve is intended to be used on higher pressure applications. The benefit of gate valves is they will be able to withstand more pressure than ball valves and can be used for more finer adjustments. In most aquarium set-ups, this valve would be overkill, unless you have a very large system that has a single return pump applying very high flow rates and high levels of pressure.

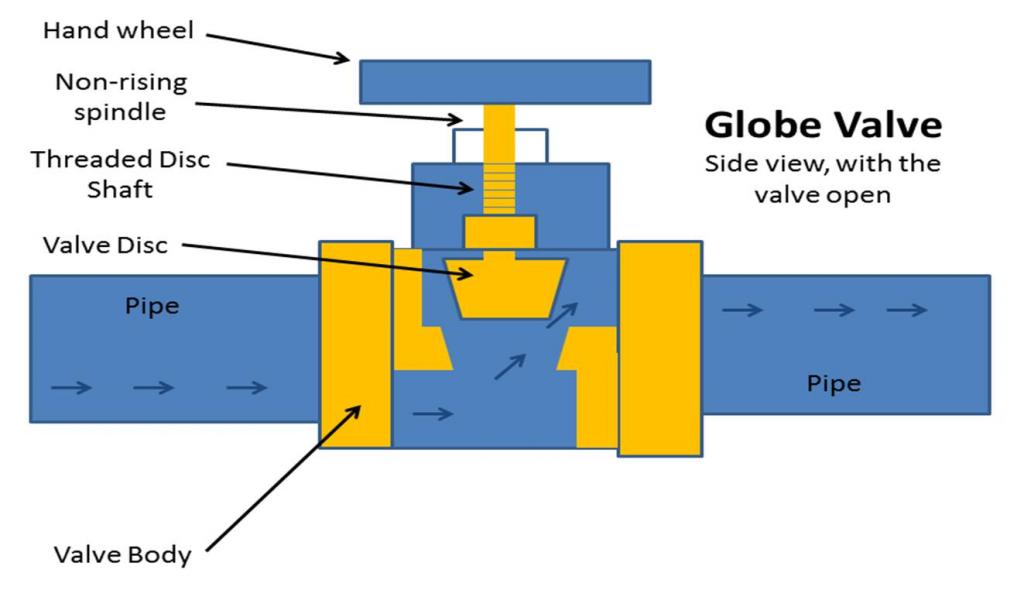

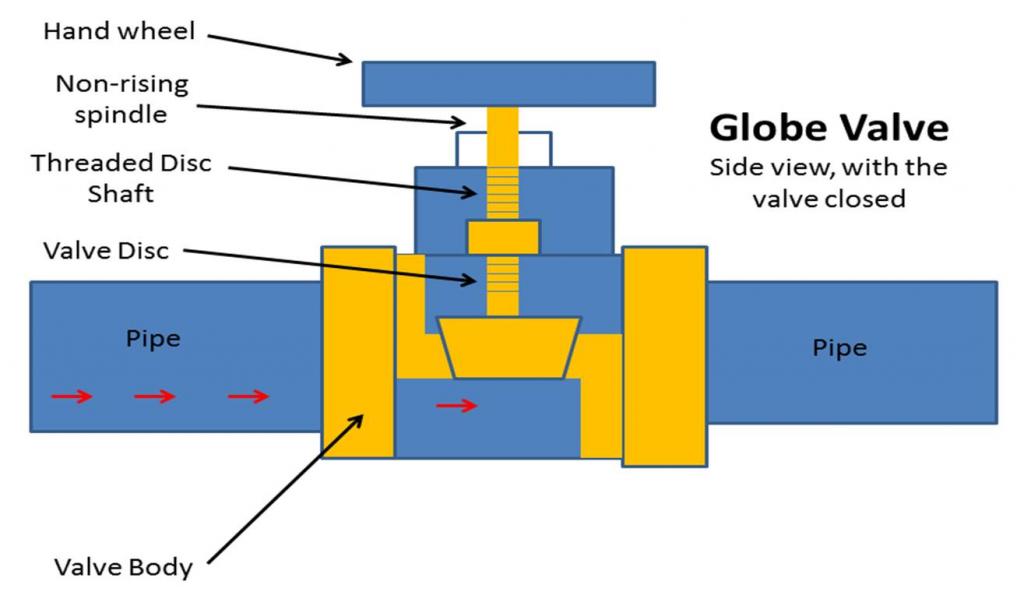

Globe Valves

These valves are the least common to find in the hobby.They can be more difficult to find globe valves made entirely out of aquarium safe materials and would most likely have to be order in by a plumbing supply company or purchased from a on-line aquarium supply company. They typically can withstand the most pressure and temperature of these three mentioned valves, but they will also restrict the water flow through it the most as well.Gate valves would be considered specialty valves to be used in very specific situations were a ball or gate valve cannot handle the pressure being put through the line.

Check Valves

Check valves are a type of valve that will only allow liquid to flow in one direction.You can not use them to control the flow of water through them.They are commonly used on return line to prevent water draining back from the display tank into the sump when the return pump is no working.When the pump is shut off, the pressure product by the water flow is removed and the valve closes preventing water from draining back.When the pump is turned back on, the pressure of the pump moving the water through the valve will open the valve returning to normal flow through the valve.The below are the two most common types of check valves used in the hobby today.

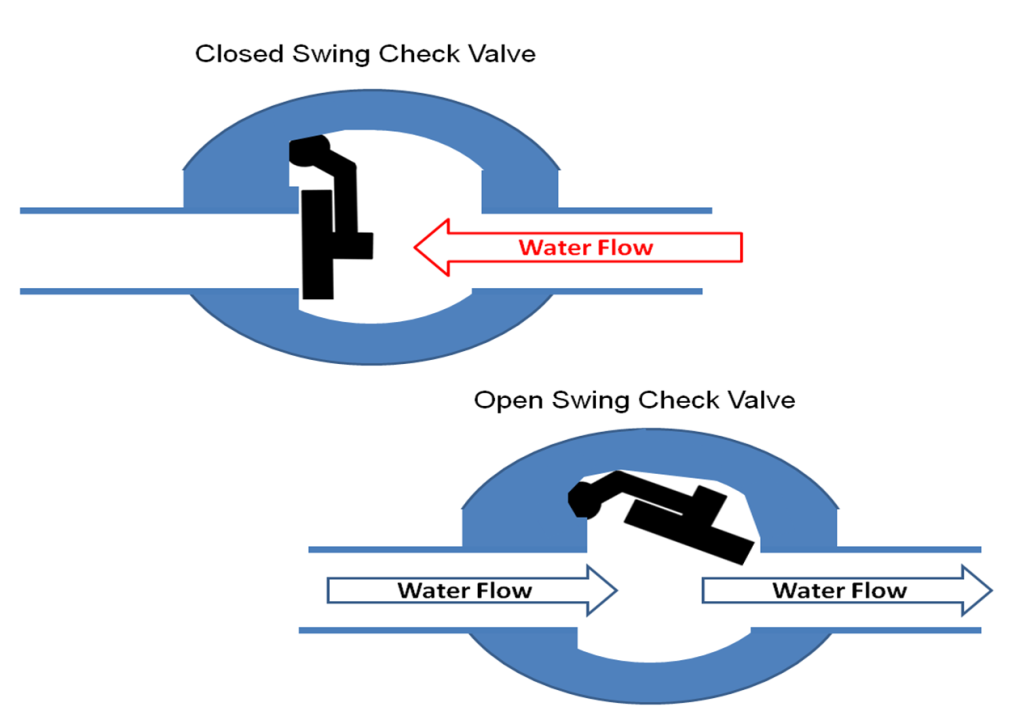

Swing Check Valve

These are the most common to find. They will restrict the flow of liquid moving through them a little.They are commonly available from on-line aquarium supply stores and maybe even plumbing supply stores. You have to be very careful when picking out a swing check valve.Lower cost valve will use a metal spring on the disc to help close the valve when the pressure / flow is removed. For that reason I do not like using swing check valves in set-ups that I want to use a check valve.

Note: there are many different designs for a swing check valve.I am only showing one of the more common swing check valve designs that come in aquarium safe material (all PVC construction).The check valves that are very slim (looking more similar to a PVC coupling) are the ones that commonly have metal spring inside. Make sure you verify they type of check valve you have before you install it on to your set-up

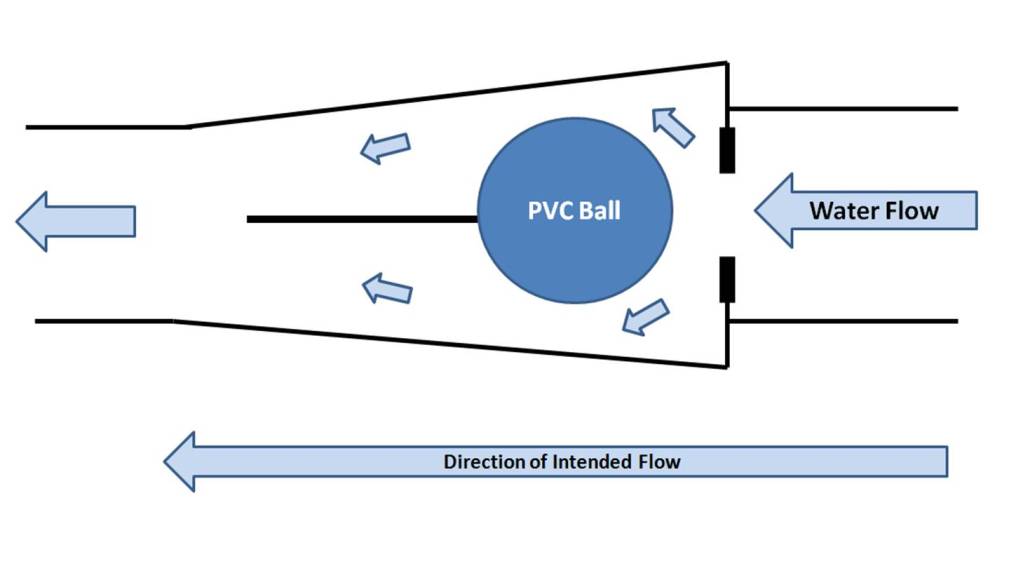

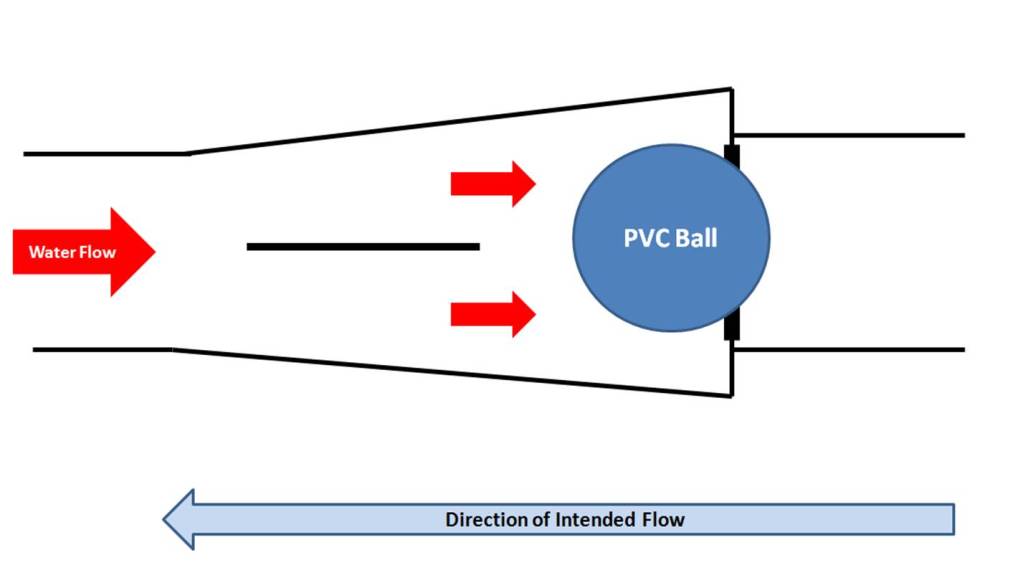

Ball Check Valve

These are less common valves and can be harder to find. You typically will have to go to a specialty plumbing supply store or a on-line aquarium supply store.They work on the same principle as a wing check valve.The only difference is that they flow pushes a ball up the body of the valve allowing water to pass around it.When the pressure/flow is removed, the ball falls onto a rubber seat and prevents water from flow backwards through the valve.They are the safest type of check valve to use as they will be made entirely of PVC material (mostly SCH 80) and they can be taken apart for cleaning and routine inspection make sure they are working properly.The only drawback ball check valves will restrict the flow of liquid moving through it more than compared to a swing check valve.

Aquarium Plumbing Pipe and Fittings

I have received many questions about which type of plumbing pipe and fittings would work best on a aquarium set-up. This article is meant to provide a little more detailed information to supplement the already posted Aquarium Plumbing Article here for those people who would like more detailed information on the commonly used tubing, pipe, and fittings used on sumped marine aquariums.

https://www.reefaquarium.com/2012/aquarium-plumbing-basics/

There are many different types of tubing, pipes, and fittings used in the hobby today.In this article I am only covering the most common types of products used.All the data listed below going to be fairly accurate, but you should assume there is a 10% variance (plus or minus) as many different variables can effect product performance making it very hard to develop a hard fast rule that applies in very situation. Use the below data a guidelines. In additional, products made outside North America may not have been manufactured up to ASTM (American Society for Testing and Materials)or CSA (Canadian Standards Association) standards making those product specifications hard to determine.That is why I always prefer to ensure the plumbing products that I purchase are manufactured to either ASTM or CSA standards to ensure the specifications will be consistent.

And just to clarify the information/data below:

-All measurements are in inches

-All pressure data is listed in PSI (pounds per square inch)

-All information on flow is listed as GHP (gallons per hour)

-Low temperature applications would include all temperatures between 30F/0C and

-Moderate temperature applications would include all temperatures between 80F/26C and 100F/38C

-High temperature applications would include temperatures higher than 100F/38C

-Schedule 40 = standard wall thickness

-Schedule 80 = extra heavy wall thickness

-Stated maximum pressures is assumed to be at maximum temperature

The below listed specifications are based on the pipe of the material type as the fittings designed to be used with each type of pipe will have slightly higher tolerances as compared with the pipe, you can find out more from The CleanUP Guys. In addition,the colors listed are the most common ones, but this can vary in Provence to Provence and State to State based on local building codes.Always read the printing on the pipe and information stamped on to the fittings to verify the type of material you have.

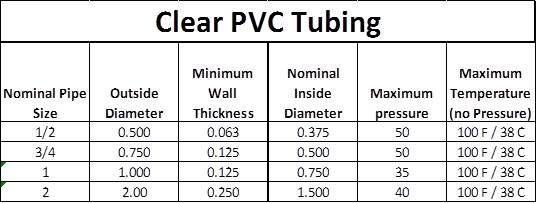

Clear PVC (polyvinyl chloride)Tubing

This is a clear and flexible plastic looking tube that is used in more of a general purpose application. It is very common to find in most hardware and plumbing supply stores.In the aquarium hobby, it is a very affordable option for low pressure and low temperature applications such as a supply and return line for a media reactor, or a low GHP return pump line. The below charts shows the specifications for clear PVC tubing.

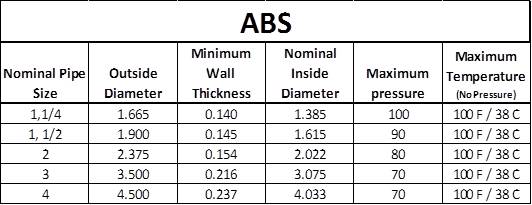

ABS (Acrylonitile Butadiene-Styrene)

This is a black ridge tube.It is most commonly used as drainage lines in many single family residential home in North America.>It is very common to find in hardware stores and plumbing supply stores. In the aquarium hobby, it is best suited to be used on drain lines from a main tank to a sump where there are higher flow rates at lower temperatures and lower pressures involved.This typically includes drain lines were the GHP is less than 1,500 to 1,800 GHP. The below chart shows some of the specifications for ABS pipe.

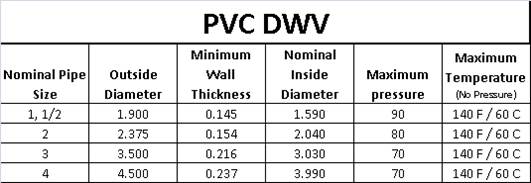

PVC DWV (polyvinyl chloride, Drain-Waste-Vent)

As an alternative to ABS, you can also use PVC DWV.This product is also used in the drainage systems for commercial and residential construction were there will be higher heat levels with minimal pressure. It is more commonly found in a littler gray color. PVC DWV will be a lot more expensive as compared to ABS and you will mostly find these products for sale in plumbing supply stores. It has very similar properties as ABS but is designed to be able to withstand higher heat levels.PVC DWV is also best suited for the same type of aquarium drain lines as ABS. The below chart will show you some of the specifications for PVC DWV pipe.

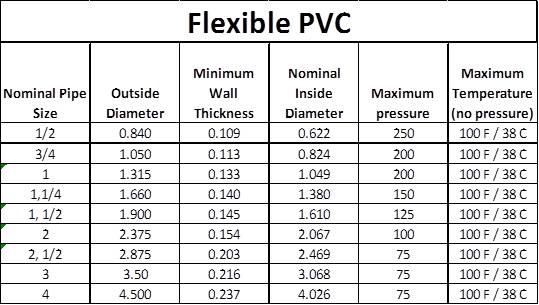

Flexible PVC (polyvinyl chloride)

This is a flexible and re-enforced PVC tubing product.It is most commonly white in color but is also made in a few other colors like gray and black.The most common application for this is for the re circulation lines on hot tubs and jetted tubs.In the aquarium hobby, you will find this product typically used on drain lines from the main tank to a sump were you need a little bit of flexibility to avoid used a rigid pipe and fitting to help reduce a loss of flow.The smaller diameters (one inch and below) can also be used on return lines were the GPH will not exceed 1,500.Flexible PVC hose is also best used for low temperature applications.This would be my preferred product for moderate flow applications. Flexible PVC tubing is designed to be used with standard (Sch 40) PVC fittings and glue. You will find some of the specifications for flexible PVC in the below chart.

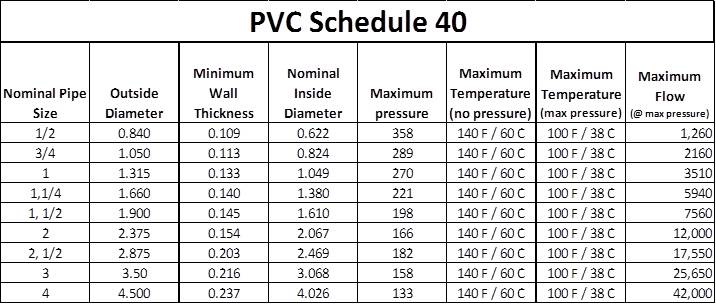

PVC (polyvinyl chloride), Schedule 40

PVC is commonly used for residential and commercial water supply and water drainage applications with low to moderate heat and moderate pressures. It is a very common product to find in most hardware stores and plumbing supply stores and is most commonly found in solid white color. PVC would be about the most common product to find being used on sumped aquarium set-ups due to the fact it can be used for a drain or return line in almost any type of set-up.This too would be my preferred product for drain and return lines for higher and lower flow set-ups.It is about the best product to use for a peace of mind. PVC SCH 40 specifications are listed in the below chart.

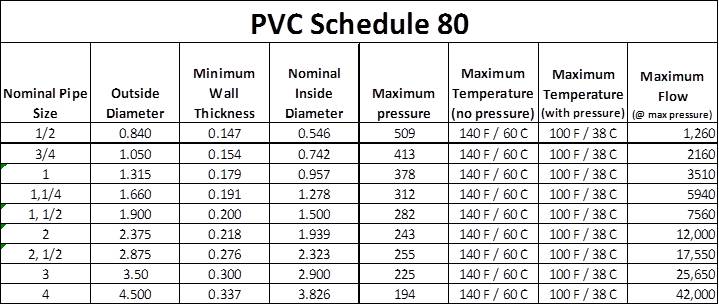

PVC (polyvinyl chloride), Schedule 80

This is just a heavy duty version of PVC SCH 40. It is a little harder to find as compared the PVC SCH 40. As this product is more commonly used in commercial applications with higher pressure and lower temperatures conditions exist. This type of PVC is commonly found in a darker gray color. It can be somewhat hard to find in most hardware stores.Typically you might need to go to a plumbing store to find a good selection of PVC SCH 80 pipe and fittings.This also is a lot more expensive than PVC SCH 40.In the aquarium hobby, you would use this product in very high flow applications that would also have higher pressures as well. You will find some of the specifications for PVC SCH 80 in the below chart.

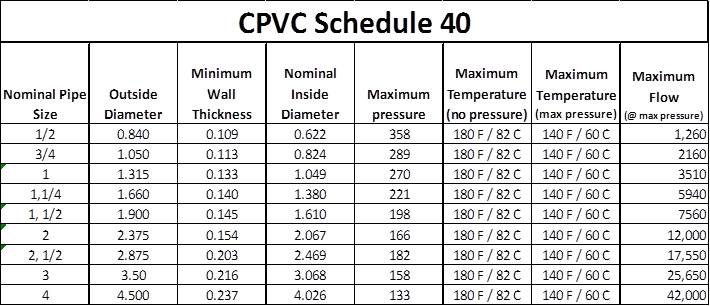

CPCV (Chlorinated polyvinyl chloride) Schedule 40

This product is very similar to PVC SCH 40 but is indented to be used in moderate and high heat applications. It is most commonly found in a lighter gray color very similar to PVC DWV. Typically you would see this being used on hot water supply lines and some drainage applications.In the aquarium hobby you can use this product just as you would PVC, however, it will cost you a little more to do it. The below chart has some of the specifications for CPVC.

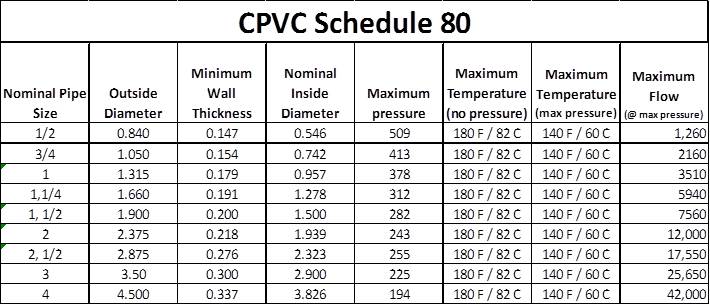

CPCV (Chlorinated polyvinyl chloride) Schedule 80

This product is very similar to PVC SCH 80 but will be able to withstand higher temperature ranges at the higher pressure levels.This product is most commonly used as hot water supply lines in commercial applications.I cannot imagine a set-up that would have high levels of heat and pressure requiring this product.You can use CPVC SCH 80 on a drain line or return line of a sumped marine aquarium, but it will cost you more money to use this product. The below charts shows some product specifications for extra heavy CPVC.

Fittings

There are a seemingly endless number of different types of fittings, each with their purpose. However, all of the fittings can be placed into one of the below 8 categories.

1) Adapters. Adapters are commonly used to go from threaded to solvent end, or solvent end to threaded ends, all available in both male/female ends.You can also get adapters to transition between different material types

2) Bushings. These are used to transition from one size of pipe to another. Bushing will also come in combinations of threaded and solvent ends as well to suit your specific needs/plans

3) Caps/plugs. These are used to close off a pipe or fitting

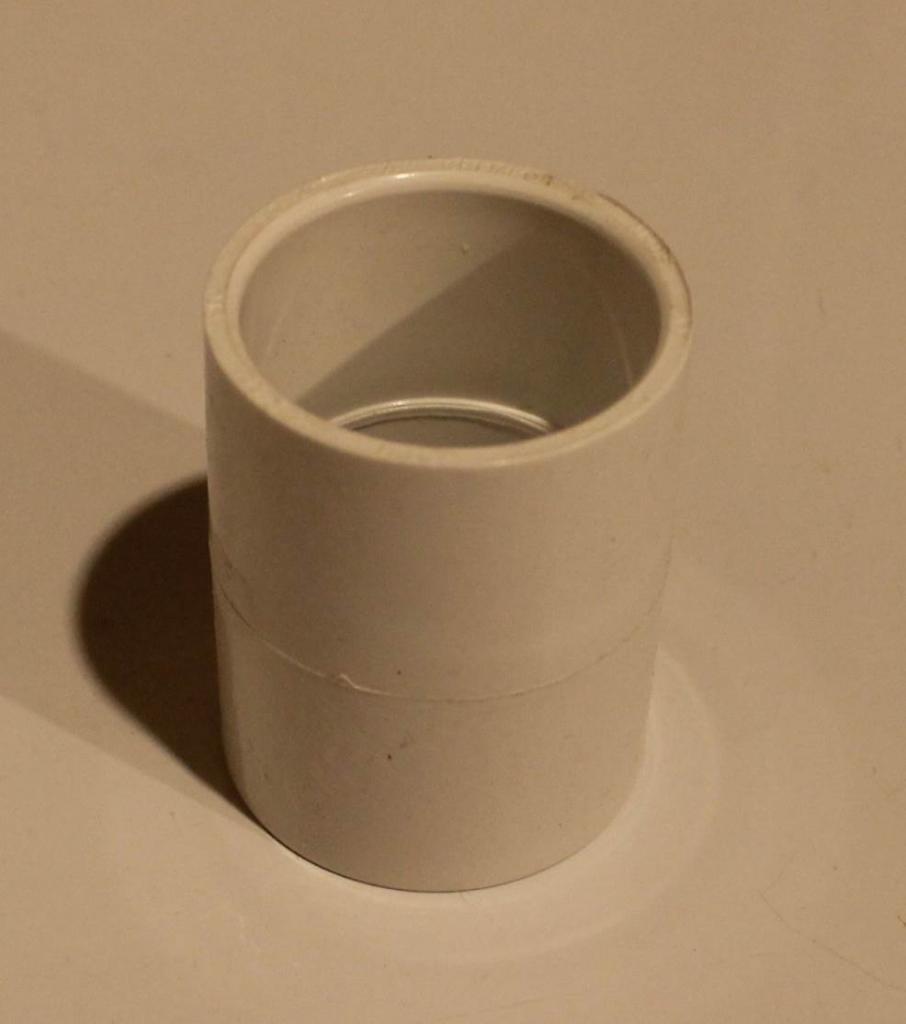

4) Couplings. These are used to connect two smaller pieces of pip together to make a longer run of pipe

5) Elbows. Just as the name suggests, they are to change the direct of the pipe in a range of angles from 22 degrees to 90 degrees. You can also get them in combinations of threaded/solvent end and male/female ends as well.

6) Flanges. These are commonly used to connect pipe to a flat surface such as the glass of a aquarium or sump, or a larger valve. These too will come in combinations of threaded and solvent applications and may also be left or right hand threaded.

7) Tees. These are used to split the direct of a pipe in two or more directions

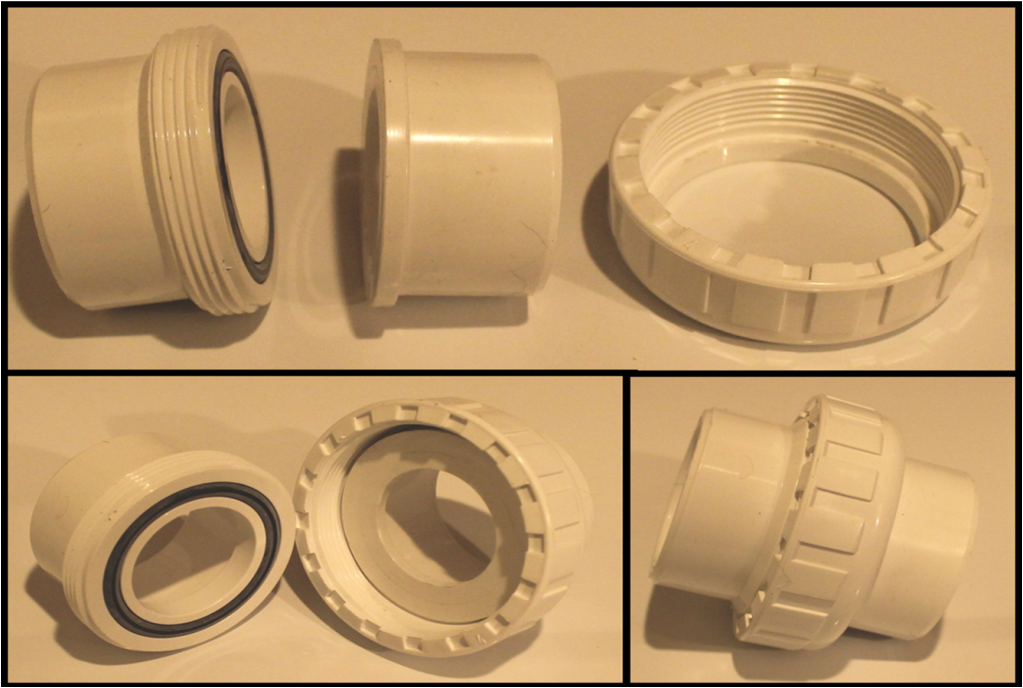

8) Unions-. These are type of couplings that are made of two halves with thread together. They allow you to quickly and easily disconnect a part of plumbing set-up and put it back together again. They also come in threaded and solvent combinations

Connecting fittings and pipe.

When using screwed fittings, it is always best to use a Teflon thread tape. This non-adhesive tape will fill in any potential gaps between the threads allowing the threaded connection to remain water tight and avoid any leaks. There are many different types of thread tape, each designed to be used with different types of materials and different applications. The most common type of thread tape that can be used in all the above listed materials will commonly be white in color and will be the most commonly found thread tape in just about any hardware store. This tape is also safe for aquarium use.

When using solvents to “glue” fittings and pipe together, please keep in mind there is a specific solvent designed to be used with each of the different material types listed above. Make sure to double check and ensure you are using the correct solvent for the type of material you are using. Using the wrong solvent can result in the joint developing a leak or even failing over time. Go ahead and check out this post to get informed on the best aquarium filters on the market.

As you may have noticed, all of the outside dimensions of the pipe listed about are all the same (as detailed in the applicable ASTM and CSA standards). If you choose to use combination of different material types you must ensure you are using the correct type of transition solvent designed to be used with both of types of materials. You can commonly find ABS/PVC DVW and PVC/CPVC transition solvents as well as a few other combinations. If you cannot find a transition solvent for both of the material types that you want to use, then you must assume you cannot use them together. When using two different material types, plan your set-up around the lower of the two specifications for the materials you are using.

Adapters. and Bushings.

Caps/plugs.

Couplings.

Elbows.

Tees

Flanges.

Unions

You can find a lot of other different plumbing products made of many different types of material, such as: Aqua-rise, Corzan PVC, Duraplas ABS, Aquatherm, and XFR PVC.Each of these have very specific uses which make them (in my opinion) not suitable for use in a sumped aquarium from a cost point of view.There are also companies that are starting to develop and market their own pipe products for use in the hobby.The below link shows an example of this.These manufactures state these products are PVC SCH 40 and can be used with regular PVC SCH 40 fittings.I cannot verify if these new products are in fact manufactured up to ASTM or CSA standards so I cannot validate the specifications these products are manufactured to.

http://reefbuilders.com/2013/08/19/pimp-aquarium-colored-pvc/

Do I need a UV Sterilizer ???

There are a lot of opposing opinions out there about the use of ultraviolet sterilizers (UV sterilizers) which can make it hard to decide if you would need to add one to your set-up. Hopefully this article can help you think through if you want to use a UV sterilizer or not and make an informed decision either way.

The first step in deciding would be to better understand what a UV sterilizer is and how it works

UV sterilizers are a very simply designed type of a filter. They contain a ultraviolet bulb protected by a water tight quartz sleeve. Water inters the sterilizer and passes over the sleeve becoming exposed to the UV light. The strength of the UV bulb can range anywhere from 9 watts to 100 watts in size. Always stick to a good brand name and follow the manufactures recommend bulb sized based on the total water volume in your set-up. Their also two main different designs, a external style filter that requires water to by pumped through it, and a internal (or completely self contained) style were you just place the filter in your aquarium and plug it in.

UV sterilizers will never: replace biological or mechanical filtration, allow you stop completing water changes, or remove excessive nutrients (nitrates and phosphate).

The second step would be to better understand the purpose of a UV sterilizer

You must first decide what you want to achieve with your UV sterilizer as there are two main purposes for setting up a UV sterilizer each of which better suited to different goals and each require a slightly different approach for use. Other than having a properly sized UV bulb, not fully understanding these approaches is the most common cause of not realizing the potential benefits of a UV sterilizer. This first approach is to help control free floating algae and algae spores. This will best be achieved by a higher flow rate through the sterilizer. As these organisms are smaller, they need less exposure time to the UV light when passing through the sterilizer to become effected by it. The second approach is to control free floating parasites. As parasites are larger in size as compared to bacteria, they will require longer exposure to the UV light which can be achieved by reducing the flow rate through the UV sterilizer. By purchasing a good brand name UV sterilizer and following the manufactured recommendations for flow rates, you will be maximizing the effectiveness of the UV sterilizer in either approach.

The third step would be understand the pros and cons of using a UV sterilizer

Based on my experiences using a UV sterilizer on one of my set-ups as well as what I have read, there can be many pros and cons with using a UV on your marine aquarium. The below are just a few of these pros and cons:

Pros:

-Reduce / control free floating algae and algae spores

-Reduce / control free floating parasites

-Help to reduce the impact of parasite outbreaks, like ick, providing you a better opportunity to treat it.

-Help to keep the water crystal clear and/or eliminate bacteria blooms in the water.

Cons

-They will not remove all parasite as they have to be free floating in order to be effected by the UV

-They will not help with the removal of existing algae in the tank and on the rocks.

-UV sterilizers have been reported to affect some chemical compounds affecting some types of aquarium supplements being dosed.

-They can reduce the diversity of free floating microorganisms which some corals and filter feeders need

-UV filters need to be accurately set-up or they will be useless

-Extra on-going maintenance of cleaning the bulb cover and expense of replacing bulbs every 6 to 12 months

-In most situations, the same benefits of using a UV can also be achieved by other methods

-There will be limited impact on ick as they are only free floating for a smaller portion of their life span.

Whether or not you use a UV can be more of a personal preference which is also based on the exact needs of your set-up as no two marine aquariums will ever be alike.

Selecting a New Skimmer

Seeing as how I just ordered a new skimmer for my 180 gallon set-up, I thought I would explain how I pick out skimmers.

Here are the three simple rules of thumb that I used to pick out a needle wheel based skimmer. These are not hard fast rules, just my own personal guidelines that I have decided to use for myself based on what I have read. Nothing really too scientific about this, just my first hand experiences combined with what I have read. You have to also keep in mind; some manufacture stated capacities are based on very specific test conditions which are not always reproducible in the average set-up resulting in a stated rating that may not always be usable or 100% applicable to real life uses. That is why I like to pick out skimmers based on the below three simple guidelines:

1. Look at the airflow ratings (Liters per hour).

The reason this is important is to try to gauge if the pump will be capable to produce a lot of fine bubbles. The higher the air rating, the better the potential performance. Although a lot of skimmers will be set to use about 10% to 25% of the maximum air intake settings on the skimmer (in liters per hour), this will still give you a somewhat usable guideline even though manufactures will state the maximum un restricted air flow the pump is capable of. Higher l/hr ratings can produce larger amounts of bubbles as well as smaller sized bubbles which are two key factors for a skimmer to work efficiently. For my set-ups, I have had great success by picking a skimmer with a L/hr that is between 5 to 10 times the total water volume of my set-ups (display tank + sump water volume)

2. Look at the water flow rating (in gallons per hour).

This is the amount of water the skimmer will move. I look at this for two reasons. The first is to make sure the skimmer will be able create strong and turbulent flow to utilize the bubbles produced and push the crud up into the skimmer cup. The second is to make sure the skimmer will be able to skim anywhere from 4 to 6 times the total water volume in the set-up. However, as the air pulled into the skimmer will offset some of the water, you must subtract at least 25% of the flow rating to get a more realistic number from the manufacture’s stated flow rate. This should give you the minimum water flow you will get out of that skimmer (worse case situation) based on average air/water mixtures. For example, if the manufacture states the skimmer pump has a flow rate of 1000 gph, you should use a flow rate of 750 gph as that is closer to the actual amount of water it will move once air has been mixed into the water.

3. Get a good quality brand name skimmer pump

Look for a good quality skimmer with a good quality skimmer pump. This will also depend on you budget to purchase a skimmer. I personally pay more attention to the skimmer pump than the brand of skimmer. Pumps such as: Sicce, Red Dragon, Diablo, and Rock rank amount the better quality skimmer pumps, but there are a lot more out there. Take the time to research the brand and read a lot of customer reviews to get some firsthand feedback.

Also, many people have their own rule of thumb about using the manufacture’s recommendations on suggested water volume ratings. Some people will say to pick a skimmer that is rated for 2 times your total water volume while others will say 1.5 times. While these suggestions can be helpful, they would be best to be used only as a starting point. In addition, that approach my work well for lower to mid quality skimmers, however, it will mostly likely be very misleading for good quality and top of the line skimmers. I would still suggest to assess the capability of the skimmer pump (using the above three guidelines) as a more accurate approach to take. As long as it can help you base your decision on a little more detailed information and less on a manufacture’s suggestions.

I also try to assume that my aquarium will always have a very high bioload. That way, I will be less likely to be up-grading my skimmer in the future. The only reason why I had to up-grade my current skimmer is that I recently up-graded the tank size but did not initially up=grade the skimmer when I went to a larger tank and sump.

When I researched and selected the new skimmer I just ordered for my 180 gallon set-up (total of 250 gallon water volume), I knew I wanted a skimmer with 1000 to 1500 GPH and 1250 to 2500 L/hr. I also wanted a very good quality brand as I have the budget that will allow for that. This certainly helped me a lot to narrow down my choices and to select my next skimmer.

Some Algae Scrubber Basics

Sometimes there just is no substitute for Mother Nature. You could make an argument that this is one of those times. While the use of algae scrubbers as a form of filtration certainly is not a new concept in the hobby, it remains a very effective and easy approach to reducing nitrates and phosphates from your marine aquarium. I thought I would share my approach to building and using an algae scrubber and what I have learned about some algae scrubber basics

Buying a Used Aquarium

Many people, such as me, prefer to try and buy a used aquarium in an effort to save some money. Not unlike many other people, I had to learn the hard way to be able to know which tanks to pass on and which ones were a good option to buy. Hopefully I can share a few things about what I have learned so others many not have to learn the hard way like I did.

Marine Aquarium Maintenance

I have seen this question asked many times by people who are considering setting up a marine tank. I thought I would put together a short article to give you an idea of the typical marine aquarium maintenance that I have completed and learned about along the way.

How to Drill a Aquarium

In the past I’ve always bought my tanks drilled if that is what I wanted. One day I asked myself, “why”. So I figured I would learn how to drill a tank and try it out for myself. No sense in paying extra for something that I can do myself. I practiced on a pc of extra glass I had left over from making my sump, just to be safe before trying it on one of my tanks. Here’s how I did it.

Continue reading

Setting-up Your First Marine Aquarium

I’ve been asked how to set-up a marine aquarium many times by people who are starting to think about getting a marine aquarium. As with all things in this hobby, there is more than one way to set-up a healthy and thriving aquarium. Before you can get to the point of a detailed step-by-step how to set-up a marine aquarium, you must first consider a few of the critical element to having a great set-up. Once you have those basic elements figured out, planning the rest of the set-up quickly starts to become really easy.

Continue reading

Quarantining New Additions

One of the toughest lessons that I had to learn the hard way is the importance of quarantining new fish before adding them to your set-up. When I was starting out in this hobby I did not use a quarantine tank and I was lucky for a quite a few years. But then my luck ran out and I had a whole tank wiped out by adding one little fish that was carrying a disease but did not show any symptoms. That was when I started learning how to quarantine fish and actuating following a quarantine process. Based on what I have read, having a tank’s complete stocking wiped out by a disease introduced from a new fish has driven more people out of the hobby than anything else. The good news is this is completely avoidable when you follow a quarantine process.

The below thread in our forum also highlights the importance if you still think it could not happen to you.