Monthly Archives: September 2013

Tip of the Week #1

When I took survival training while I was in the army, we were always instructed to get enough firewood to last you through the night and to complete this task before sunset.Once you had what you thought was enough firewood, get three times more fire wood that what you have. I have found this same simple principle should be applied to planning and learning about your marine aquariums.Once you think you have read and researched enough, you could stand to research some more (me included).

I have found the best way to accomplish this is by reading books and articles published by credible and experienced hobbyists combined with talking to fellow hobbyist and taking a good look at how they have set-up their aquariums. Forums and blogs can be very helpful for you fill in the gaps or help you decide between the many options and approaches you are going to become exposed to. This also is one of the aspects of the hobby that many people enjoy almost as much as they enjoy their aquariums itself.

The below are some articles that I found interesting and I thought I would share them.

http://reefbuilders.com/2013/09/09/gobiodon-species-red-sea/

http://reefbuilders.com/2013/09/09/life-spectrum-max-feeding-finicky-fish/

Building a Aquarium Canopy

I had a few requests to write up ideas with pictures of how to build a aquarium canopy.I thought I would just show and explain how I built some of the canopies that I have used in the past. The first two examples are based on a canopy that I had seen on a 190 gallon aquarium owned by a fellow hobbyist and friend.

Before building your canopy, I would recommend that you first have your lighting you are going to use on the aquarium. You will need to know how far above the aquarium you will want to use your lighting, how thick the lighting fixture is, and how long the lighting fixture is. Sometimes it is helpful if you can use your lighting on the aquarium for a while so you can try out the lighting and confirm how high you want the lighting from the top of the aquarium.

Canopy Example #1

This first example is a canopy that I built for a four foot 90 gallon aquarium.I started by building the frame that sits on top of the tank. The outside measurements of this frame are the same as the outside measurement of the aquarium. My lighting will not be wider than the aquarium so I can use those dimensions for this build. I used 2X2 inch lengths of solid pine for the back and sides and a ¾ by 4 inch length of solid pine for the front.I used construction grade wood screws and generous amounts of wood glue to attach the frame pieces together.

On this frame piece you will only see one angled support on the right hand side back corner.I could not add angled supports on both back corners as the aquarium has an internal overflow on the back left hand corner and I wanted to leave as much room as I could for access to the overflow. If the aquarium did not have an internal overflow, I would have added angled supports to both back corners

I then added the back piece to the frame (using wood glue and screws). The paneling that I used for this was ¾” solid pine. I pre-drilled holes for the screws to help ensure I did not split the wood. When working with wood 2 inches and less in thickness, I always prefer to pre-drill before using construction grade screws. When working with a softer wood like pine, you may not have to pre-drill your holes.This is just my preference

The sides were added next.As you can see from the below and above pictures, I attached the sides and back from the inside of the canopy and not from the outside were ever possible. That way, the screw heads will not be visible from the outside of the stand so I don’t have to spend as much time filling the holes to hide them later on. The back and side pieces also go 2 inches down past the frame to allow the sides and back to fit around the aquarium preventing the canopy from being accidentally knocked off the aquarium. This also covers the black trim of the aquarium giving it a nicer or at least a more consistent look

As I am using LED lighting I knew that I wanted to have them 6 to 8 inches above the aquarium, and the LED fixtures are 2 inches thick with 1 to 2 inch thick mounting bar (depending on the exact type that I choose to use). I left 10 inches of space above the frame to allow enough space inside the canopy for my lighting and air circulation around the lighting

That is why I used 14 inch wide boards for the back and sides: 10 inches of space above the frame, 2 inches of space for the frame, and 2 inches of space below the frame

I then cut and attached a piece of wood that covered about 80% of the top of the canopy, leaving about 20% of the top open at the front.

I built the lid next and dry fit it to make sure I got it right. I built an “L” shaped lid so the hinge will sit on the top of the canopy were it will be out of sight. The front of the door drops down 2 inches past the frame so it will match the sides and back of the canopy.

As you can see by the below picture, I used four angled supports to re-enforce the two pieces of the lid.

The next step was to drill the vent holes on the sides, top and back, and put in the rails for the LED mount bar I made. I also added a little trim to the sides to give it a little better look. The inside rails can also be used for a T5 light fixture as well. The second example that I have in this article shows these rails in better detail.

After some wood filler, two coats of a good quality primer & sealer, and 3 coats of a marine based paint, the canopy was complete. You can also use a very good quality primer and sealer followed by a very good quality exterior paint if you do not want to use a marine based paint. I had to let the paint cure before I put it on the aquarium. I painted the inside with the same black paint as I did not want to buy two different colors of marine paint

I chose to paint this canopy black so it would match the stand the aquarium was sitting on. I like to give my set-ups a more consistent look as well as matching with the rest of the furniture in the room, but that is just my preference. You can finish your canopy to suit your tastes.

Here are a few pictures of the finished product.

Canopy Example #2

The second example that I am showing here is one that I built for a four foot 120 gallon aquarium that I have. I wish I had taken more photos while I was building it, but this will give you a pretty good idea. I followed the basic same design as the first canopy that I showed in this article. The biggest difference is that I stained and urethaned this canopy and extended the top of the door to the center of the top of the canopy to allow for more room to reach into the tank to complete routine maintenance when needed. The only drawback to this is that it makes the door heavier as compared to the door in the first example.

In these pictures you will see a little more detail on a few features not shown very well on the first example. I also drilled two air holes on each side of the back piece near the corner to run cables through for the poweheads, lighting, and what not. I made these holes a little larger than the rest of the air hole to make it easier when running cable through them. You can also see the vent holes that were drilled on the top of the canopy for additional air circulation.

Just as with the first canopy, I used the same thickness of solid pine and I glued and screwed everything together in the same way. I stained this canopy to match the stand and furniture in the room followed by several coats of urethane (4 or 5 if I am remembering correctly).

One of the last things that I had done was to add two pieces of wood on the inside of each side for the mounting bar of my LED lighting to sit on. You can also adjust the height of this wooden rail to allow for a T5HO fixture.

I had to make sure the angled supports on the back corners of the frame would not extend further past the top bracing of the aquarium or they would restrict my access to the internal overflow.You can also see the side trim pieces that I added to give the canopy a more finished look and to also hide any light that might come through around the door.

If you are using T5HO or MH lighting I would certainly recommend more and larger vent holes and possibly adding a built in vent fan or two. I would also design the canopy for extra space inside the canopy for better air movement to help the lighting stay cool. You will have to be extremely careful using MH lighting in a canopy due to the very high levels of heat produced by an average MH fixture. As I use LEDs in my canopies I do not need that many vent holes as they produce low amounts of heat.

The below is a picture showing the air vent covers that I added to the sides once the store got more in. These can be found in most home improvement and hardware stores were they keep the roofing products.These vent covers are actually meant to cover roof ventilation holes in the soffits of most homes. I like using them on my canopys as they allow for very good airflow while preventing a lot of light from getting through.

Canopy Example #3

The third example is a canopy that I built for a six foot 180 gallon aquarium.The frame, sides and back were built the same as in the first two examples.I did add additional framing in the middle of the canopy to support the 6 foot span of the top of the canopy. As you can see by the below picture, I had added two sets of mounting rails as I was planning to use two sets of hanging bars for the LED lighting to be used on this aquarium.

The biggest difference with this canopy is that the doors open out from the center of the front of the canopy and are hinged on each side of the front. The top piece that sits in the opening pictured in the above picture is not actually attached to the top of the canopy making it removable for easy aquarium maintenance when required.The below pictures better illustrate what I am talking about.

As this aquarium has an external overflow on the back of the aquarium, I had cut out two access holes in the back of the canopy above the overflows for easier access/maintenance to the duriso stand pipes in the overflow without having to remove the canopy to get to them. I had cut this out after I finished building the stand to make things a little easier

Aquarium Plumbing Valves

I have received a lot of questions about using valves on aquarium set-ups. This article is meant to provide a little more detailed information to supplement the already posted Aquarium Plumbing Article here for those people who would like more detailed information on the commonly used valves on sumped marine aquariums.

https://www.reefaquarium.com/2012/aquarium-plumbing-basics/

There are many different types of valves used in the hobby today.In the article I am only covering the most common types of products used. All the information listed below is some accurate but you should assume there are many different variables can effect product performance making it very hard to develop a hard fast rule that applies in very situation. Use the below as guidelines. In additional, products made outside North America not have been manufactured up to ASTM, (American Society for Testing and Materials)or CSA (Canadian Standards Association) standards making those product specifications hard to determine.That is why I always prefer to ensure the plumbing products that I purchase are manufactured to either ASTM or CSA standards to ensure the specifications will be consistent.

Please keep in mind, there are seemingly hundreds of different types of plumbing companies but it is important that you choose one of the best plumbing companies who has the right knowledge.The valves that I am referring to in this article are the ones that I have come across that can be made with materials that are aquarium safe and are also suited for the typical sumped aquarium set-up.

Regular Valves

I would refer to any valve that is used to regulate or completely shut off (stop) flow as a regular valve.The below valves are the most common valves that I have found in the hobby so far.

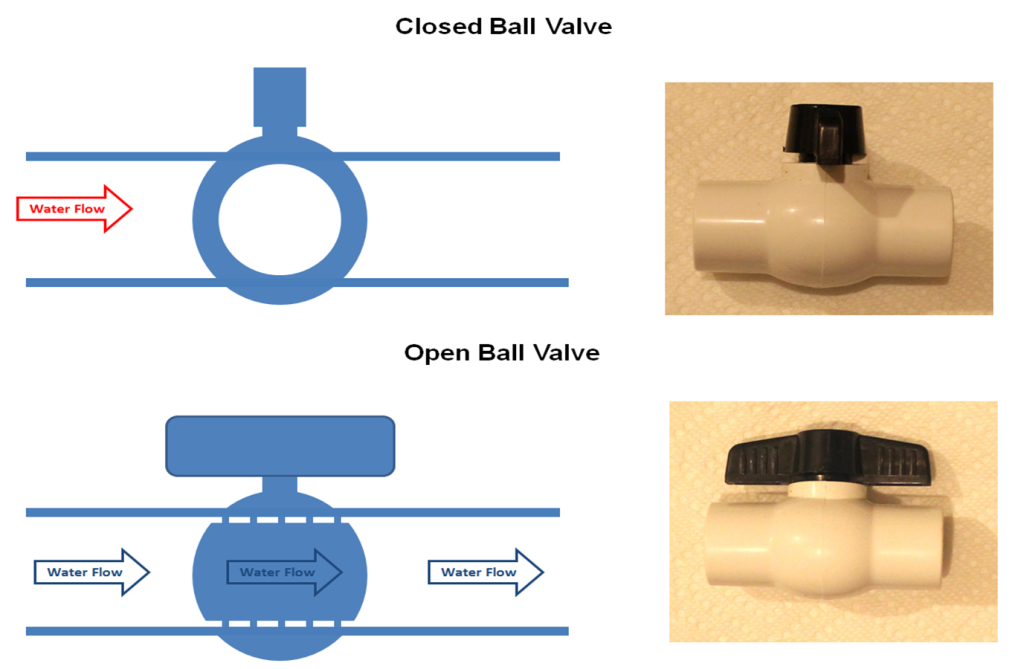

Ball Valves

These are about the most common style of valve that you will find in use in the aquarium hobby.They are very easy to find in most hardware and plumbing supply stores in models that are made with materials that are safe for aquarium use.The models that are made of PVC material range in size for ½ to 6 inches.You can get them in SCH 40 and SCH 80 PVC which will have the same tolerances and specifications as the same PVC pipe and fittings. Ball valves are also available in screwed or socket weld (glued) connections depending on how you want to connect this valve into your system.This is my preferred valve to use in any type of plumbing set-up.The reason for this is that ball valves will restrict the flow going through the valve the least of any type and they are also the least likely to fail or leak.The only drawback to using these valves in PVC is that they are not the best suited for high pressure and high heat unless you have a ball valve made of PVC SCH 80.

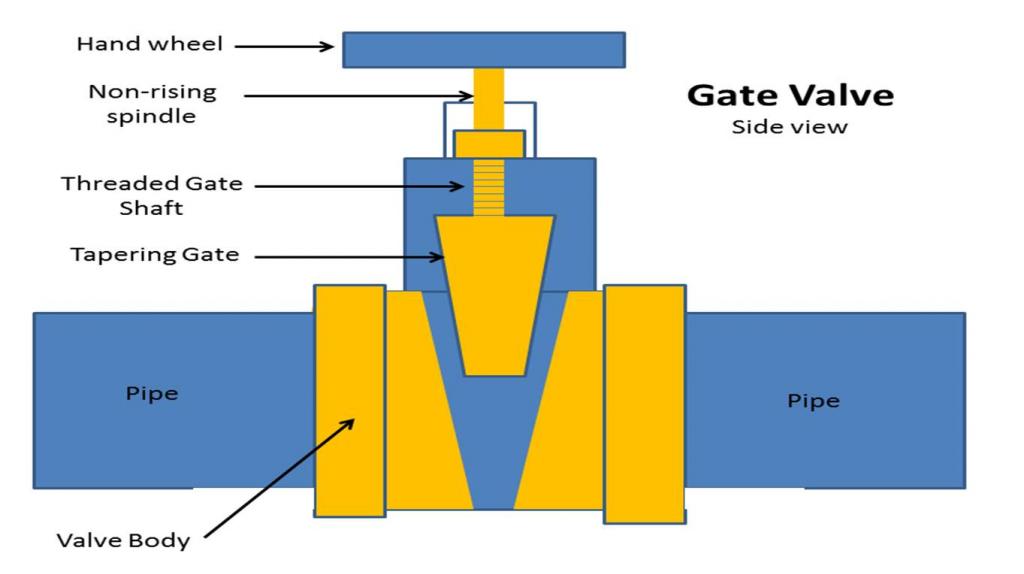

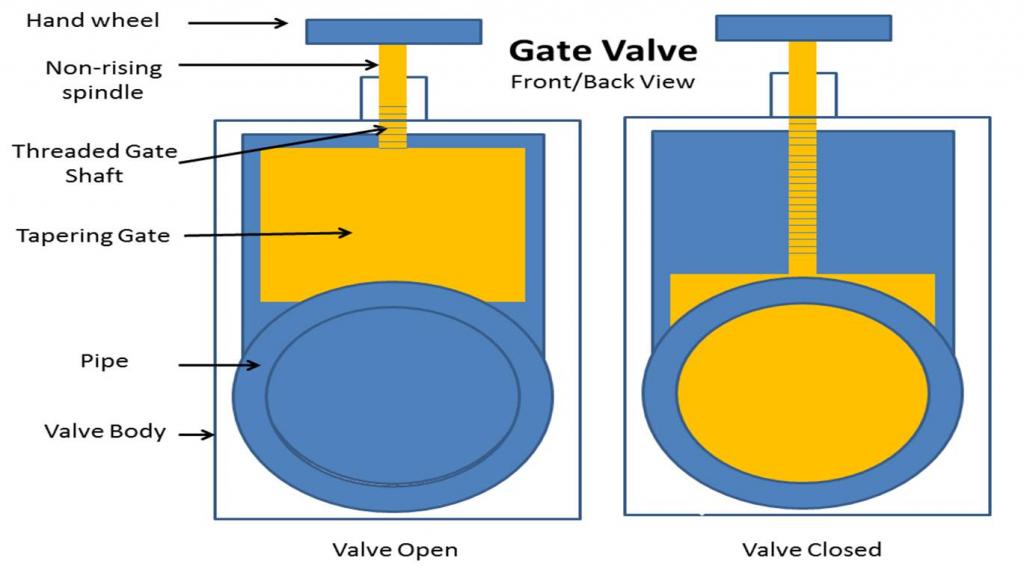

Gate Valves

These valves are somewhat common to find in the hobby.They will reduce the flow going through them more than compared to a ball valve. Gate valves made in PVC are harder to find, mostly being found in plumbing supply stores or some on-line aquarium supply stores. The can also com in PVC SHC 40 and PVC SCH 80 material but are more common to find in SCH 80 as the valve is intended to be used on higher pressure applications. The benefit of gate valves is they will be able to withstand more pressure than ball valves and can be used for more finer adjustments. In most aquarium set-ups, this valve would be overkill, unless you have a very large system that has a single return pump applying very high flow rates and high levels of pressure.

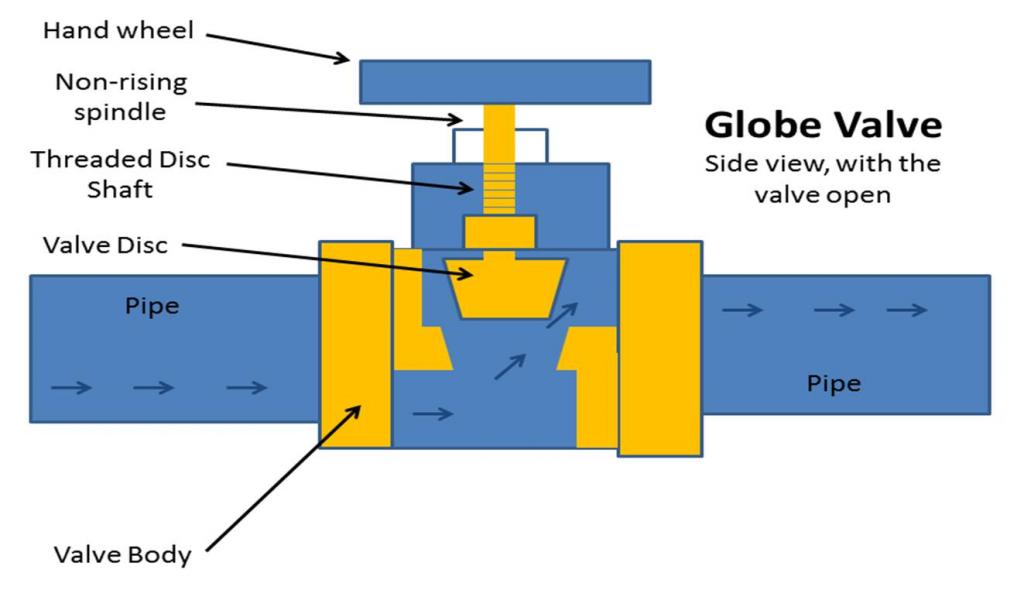

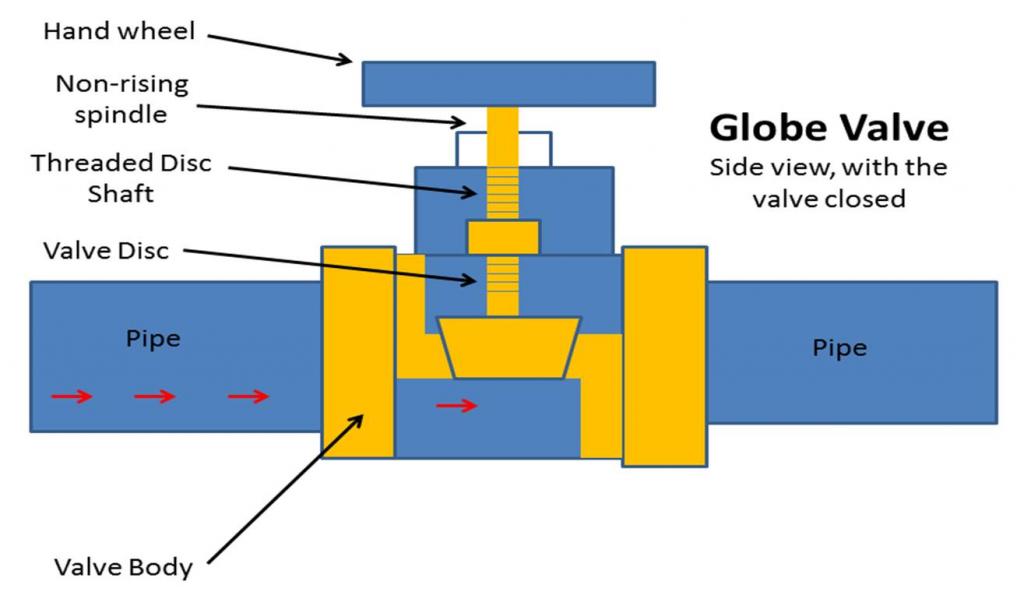

Globe Valves

These valves are the least common to find in the hobby.They can be more difficult to find globe valves made entirely out of aquarium safe materials and would most likely have to be order in by a plumbing supply company or purchased from a on-line aquarium supply company. They typically can withstand the most pressure and temperature of these three mentioned valves, but they will also restrict the water flow through it the most as well.Gate valves would be considered specialty valves to be used in very specific situations were a ball or gate valve cannot handle the pressure being put through the line.

Check Valves

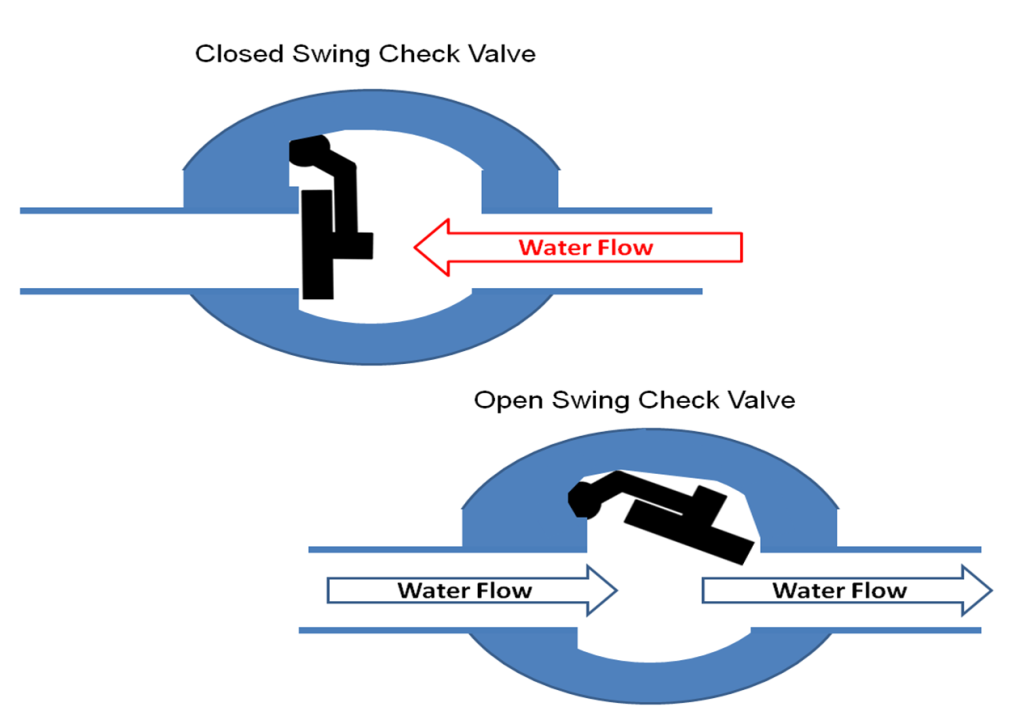

Check valves are a type of valve that will only allow liquid to flow in one direction.You can not use them to control the flow of water through them.They are commonly used on return line to prevent water draining back from the display tank into the sump when the return pump is no working.When the pump is shut off, the pressure product by the water flow is removed and the valve closes preventing water from draining back.When the pump is turned back on, the pressure of the pump moving the water through the valve will open the valve returning to normal flow through the valve.The below are the two most common types of check valves used in the hobby today.

Swing Check Valve

These are the most common to find. They will restrict the flow of liquid moving through them a little.They are commonly available from on-line aquarium supply stores and maybe even plumbing supply stores. You have to be very careful when picking out a swing check valve.Lower cost valve will use a metal spring on the disc to help close the valve when the pressure / flow is removed. For that reason I do not like using swing check valves in set-ups that I want to use a check valve.

Note: there are many different designs for a swing check valve.I am only showing one of the more common swing check valve designs that come in aquarium safe material (all PVC construction).The check valves that are very slim (looking more similar to a PVC coupling) are the ones that commonly have metal spring inside. Make sure you verify they type of check valve you have before you install it on to your set-up

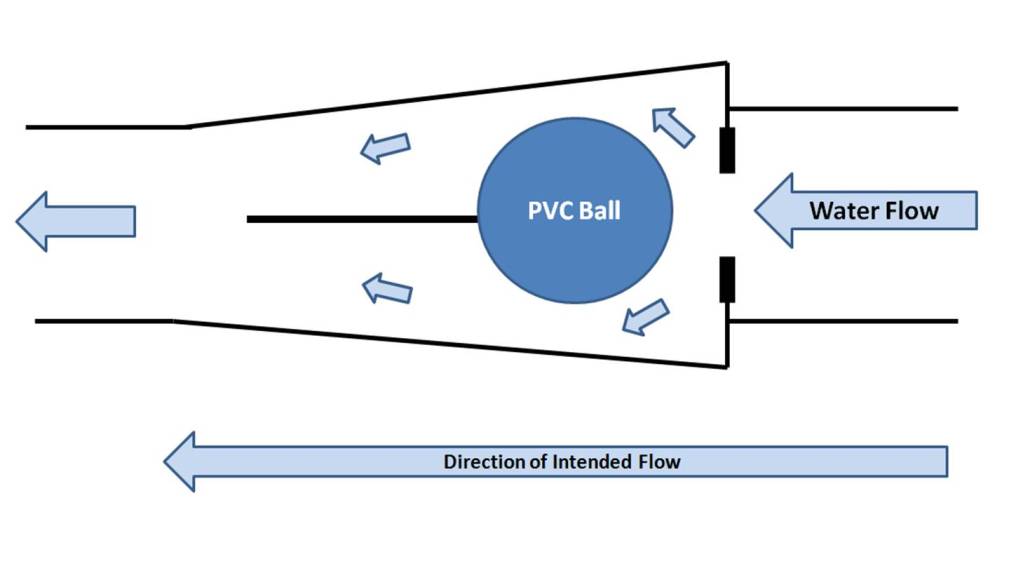

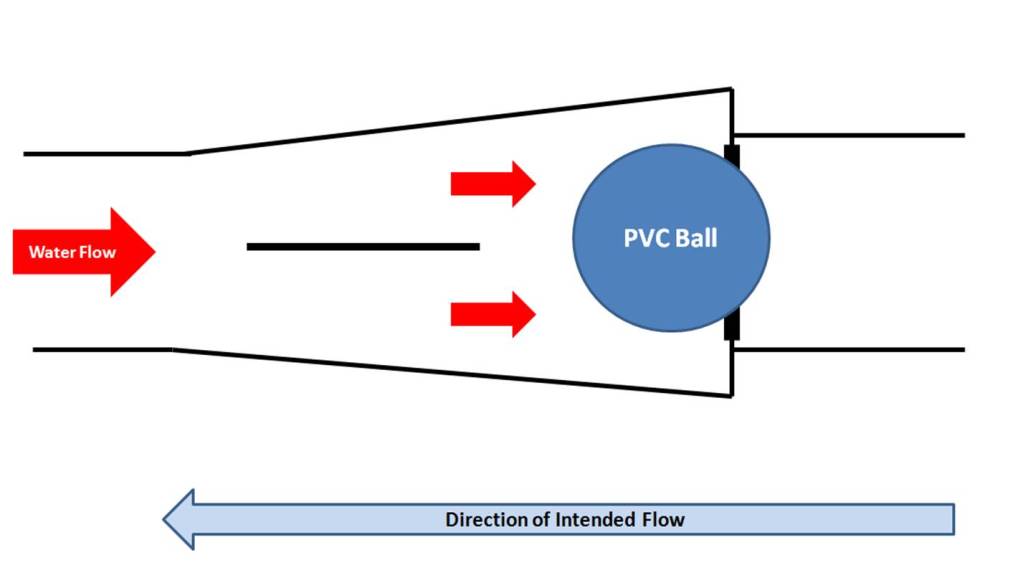

Ball Check Valve

These are less common valves and can be harder to find. You typically will have to go to a specialty plumbing supply store or a on-line aquarium supply store.They work on the same principle as a wing check valve.The only difference is that they flow pushes a ball up the body of the valve allowing water to pass around it.When the pressure/flow is removed, the ball falls onto a rubber seat and prevents water from flow backwards through the valve.They are the safest type of check valve to use as they will be made entirely of PVC material (mostly SCH 80) and they can be taken apart for cleaning and routine inspection make sure they are working properly.The only drawback ball check valves will restrict the flow of liquid moving through it more than compared to a swing check valve.

Aquarium Plumbing Pipe and Fittings

I have received many questions about which type of plumbing pipe and fittings would work best on a aquarium set-up. This article is meant to provide a little more detailed information to supplement the already posted Aquarium Plumbing Article here for those people who would like more detailed information on the commonly used tubing, pipe, and fittings used on sumped marine aquariums.

https://www.reefaquarium.com/2012/aquarium-plumbing-basics/

There are many different types of tubing, pipes, and fittings used in the hobby today.In this article I am only covering the most common types of products used.All the data listed below going to be fairly accurate, but you should assume there is a 10% variance (plus or minus) as many different variables can effect product performance making it very hard to develop a hard fast rule that applies in very situation. Use the below data a guidelines. In additional, products made outside North America may not have been manufactured up to ASTM (American Society for Testing and Materials)or CSA (Canadian Standards Association) standards making those product specifications hard to determine.That is why I always prefer to ensure the plumbing products that I purchase are manufactured to either ASTM or CSA standards to ensure the specifications will be consistent.

And just to clarify the information/data below:

-All measurements are in inches

-All pressure data is listed in PSI (pounds per square inch)

-All information on flow is listed as GHP (gallons per hour)

-Low temperature applications would include all temperatures between 30F/0C and

-Moderate temperature applications would include all temperatures between 80F/26C and 100F/38C

-High temperature applications would include temperatures higher than 100F/38C

-Schedule 40 = standard wall thickness

-Schedule 80 = extra heavy wall thickness

-Stated maximum pressures is assumed to be at maximum temperature

The below listed specifications are based on the pipe of the material type as the fittings designed to be used with each type of pipe will have slightly higher tolerances as compared with the pipe, you can find out more from The CleanUP Guys. In addition,the colors listed are the most common ones, but this can vary in Provence to Provence and State to State based on local building codes.Always read the printing on the pipe and information stamped on to the fittings to verify the type of material you have.

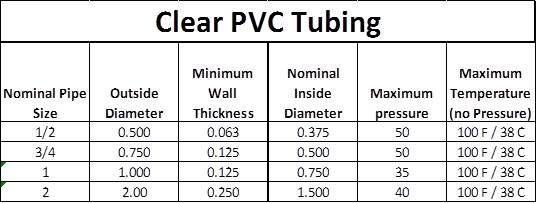

Clear PVC (polyvinyl chloride)Tubing

This is a clear and flexible plastic looking tube that is used in more of a general purpose application. It is very common to find in most hardware and plumbing supply stores.In the aquarium hobby, it is a very affordable option for low pressure and low temperature applications such as a supply and return line for a media reactor, or a low GHP return pump line. The below charts shows the specifications for clear PVC tubing.

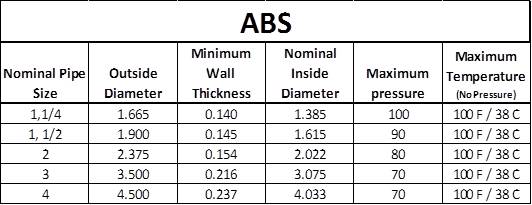

ABS (Acrylonitile Butadiene-Styrene)

This is a black ridge tube.It is most commonly used as drainage lines in many single family residential home in North America.>It is very common to find in hardware stores and plumbing supply stores. In the aquarium hobby, it is best suited to be used on drain lines from a main tank to a sump where there are higher flow rates at lower temperatures and lower pressures involved.This typically includes drain lines were the GHP is less than 1,500 to 1,800 GHP. The below chart shows some of the specifications for ABS pipe.

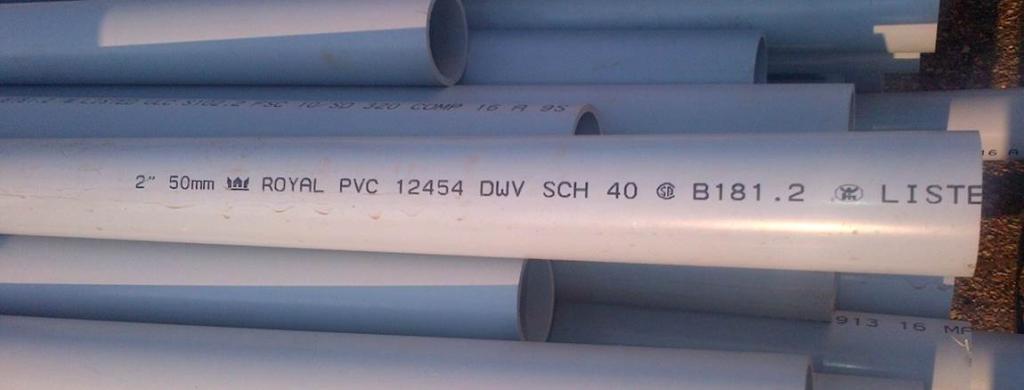

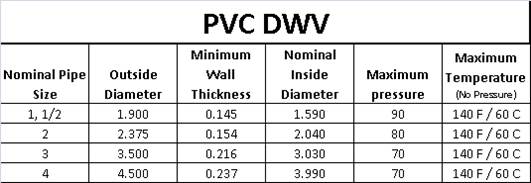

PVC DWV (polyvinyl chloride, Drain-Waste-Vent)

As an alternative to ABS, you can also use PVC DWV.This product is also used in the drainage systems for commercial and residential construction were there will be higher heat levels with minimal pressure. It is more commonly found in a littler gray color. PVC DWV will be a lot more expensive as compared to ABS and you will mostly find these products for sale in plumbing supply stores. It has very similar properties as ABS but is designed to be able to withstand higher heat levels.PVC DWV is also best suited for the same type of aquarium drain lines as ABS. The below chart will show you some of the specifications for PVC DWV pipe.

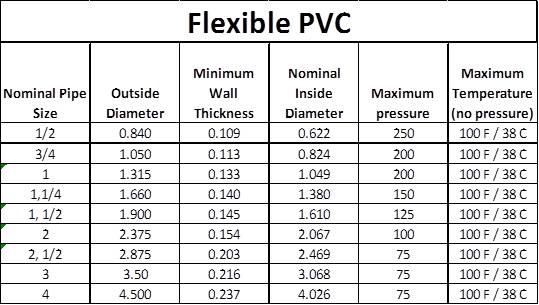

Flexible PVC (polyvinyl chloride)

This is a flexible and re-enforced PVC tubing product.It is most commonly white in color but is also made in a few other colors like gray and black.The most common application for this is for the re circulation lines on hot tubs and jetted tubs.In the aquarium hobby, you will find this product typically used on drain lines from the main tank to a sump were you need a little bit of flexibility to avoid used a rigid pipe and fitting to help reduce a loss of flow.The smaller diameters (one inch and below) can also be used on return lines were the GPH will not exceed 1,500.Flexible PVC hose is also best used for low temperature applications.This would be my preferred product for moderate flow applications. Flexible PVC tubing is designed to be used with standard (Sch 40) PVC fittings and glue. You will find some of the specifications for flexible PVC in the below chart.

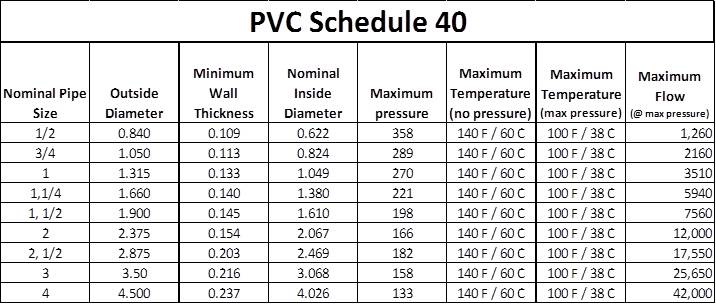

PVC (polyvinyl chloride), Schedule 40

PVC is commonly used for residential and commercial water supply and water drainage applications with low to moderate heat and moderate pressures. It is a very common product to find in most hardware stores and plumbing supply stores and is most commonly found in solid white color. PVC would be about the most common product to find being used on sumped aquarium set-ups due to the fact it can be used for a drain or return line in almost any type of set-up.This too would be my preferred product for drain and return lines for higher and lower flow set-ups.It is about the best product to use for a peace of mind. PVC SCH 40 specifications are listed in the below chart.

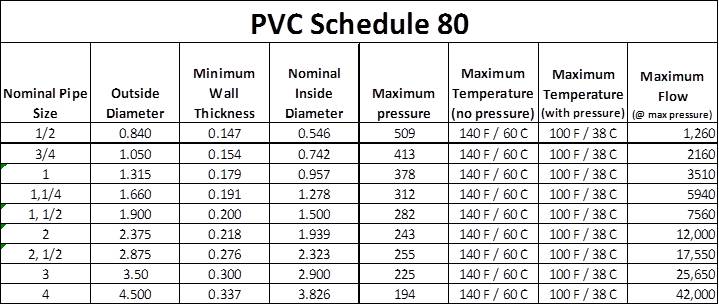

PVC (polyvinyl chloride), Schedule 80

This is just a heavy duty version of PVC SCH 40. It is a little harder to find as compared the PVC SCH 40. As this product is more commonly used in commercial applications with higher pressure and lower temperatures conditions exist. This type of PVC is commonly found in a darker gray color. It can be somewhat hard to find in most hardware stores.Typically you might need to go to a plumbing store to find a good selection of PVC SCH 80 pipe and fittings.This also is a lot more expensive than PVC SCH 40.In the aquarium hobby, you would use this product in very high flow applications that would also have higher pressures as well. You will find some of the specifications for PVC SCH 80 in the below chart.

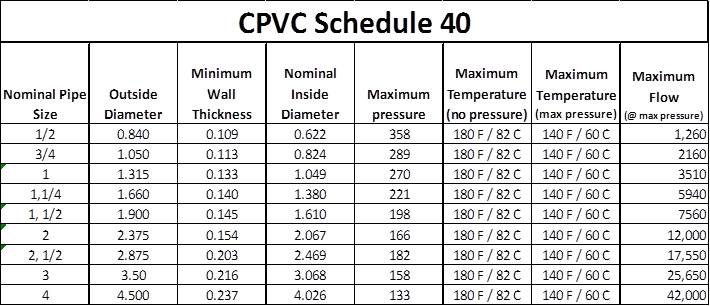

CPCV (Chlorinated polyvinyl chloride) Schedule 40

This product is very similar to PVC SCH 40 but is indented to be used in moderate and high heat applications. It is most commonly found in a lighter gray color very similar to PVC DWV. Typically you would see this being used on hot water supply lines and some drainage applications.In the aquarium hobby you can use this product just as you would PVC, however, it will cost you a little more to do it. The below chart has some of the specifications for CPVC.

CPCV (Chlorinated polyvinyl chloride) Schedule 80

This product is very similar to PVC SCH 80 but will be able to withstand higher temperature ranges at the higher pressure levels.This product is most commonly used as hot water supply lines in commercial applications.I cannot imagine a set-up that would have high levels of heat and pressure requiring this product.You can use CPVC SCH 80 on a drain line or return line of a sumped marine aquarium, but it will cost you more money to use this product. The below charts shows some product specifications for extra heavy CPVC.

Fittings

There are a seemingly endless number of different types of fittings, each with their purpose. However, all of the fittings can be placed into one of the below 8 categories.

1) Adapters. Adapters are commonly used to go from threaded to solvent end, or solvent end to threaded ends, all available in both male/female ends.You can also get adapters to transition between different material types

2) Bushings. These are used to transition from one size of pipe to another. Bushing will also come in combinations of threaded and solvent ends as well to suit your specific needs/plans

3) Caps/plugs. These are used to close off a pipe or fitting

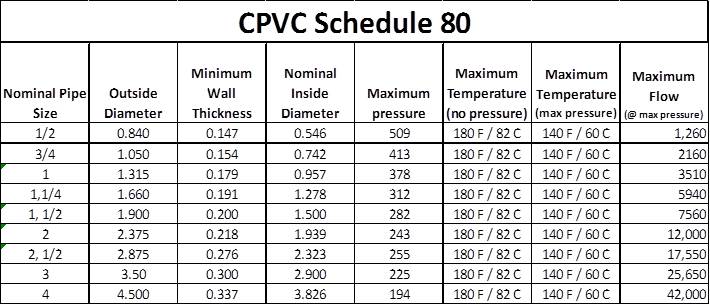

4) Couplings. These are used to connect two smaller pieces of pip together to make a longer run of pipe

5) Elbows. Just as the name suggests, they are to change the direct of the pipe in a range of angles from 22 degrees to 90 degrees. You can also get them in combinations of threaded/solvent end and male/female ends as well.

6) Flanges. These are commonly used to connect pipe to a flat surface such as the glass of a aquarium or sump, or a larger valve. These too will come in combinations of threaded and solvent applications and may also be left or right hand threaded.

7) Tees. These are used to split the direct of a pipe in two or more directions

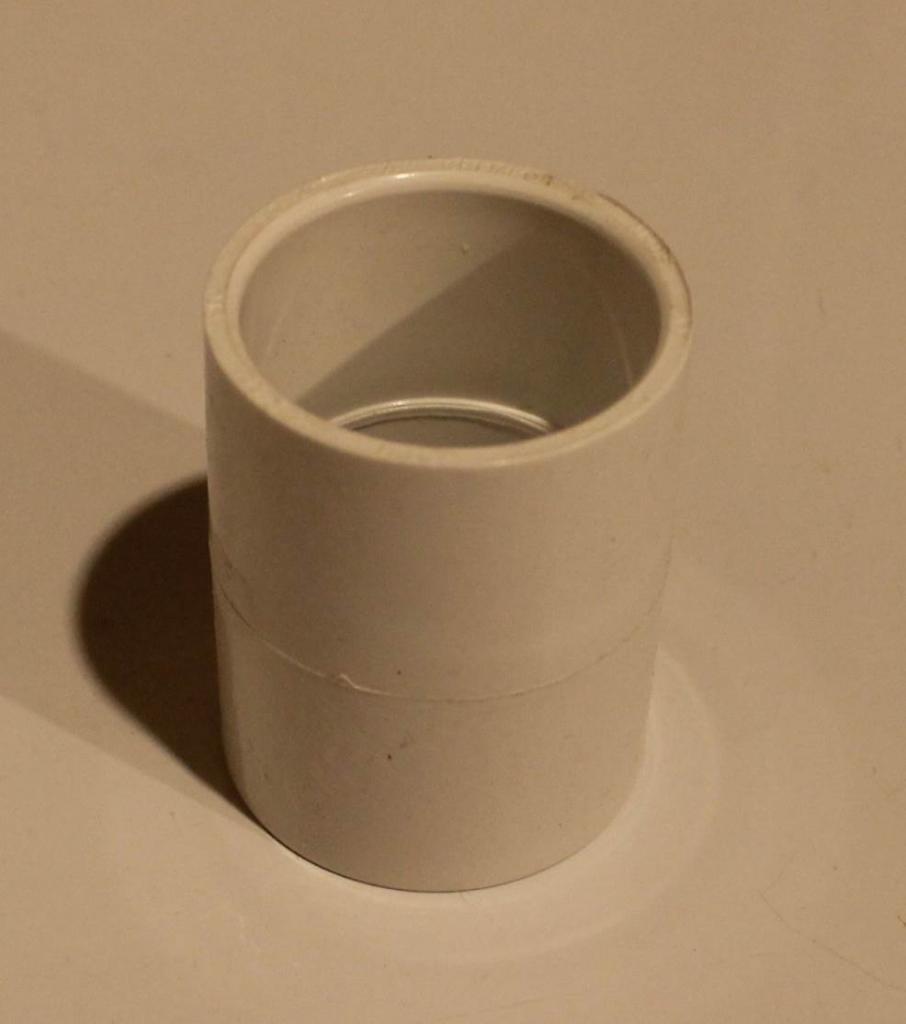

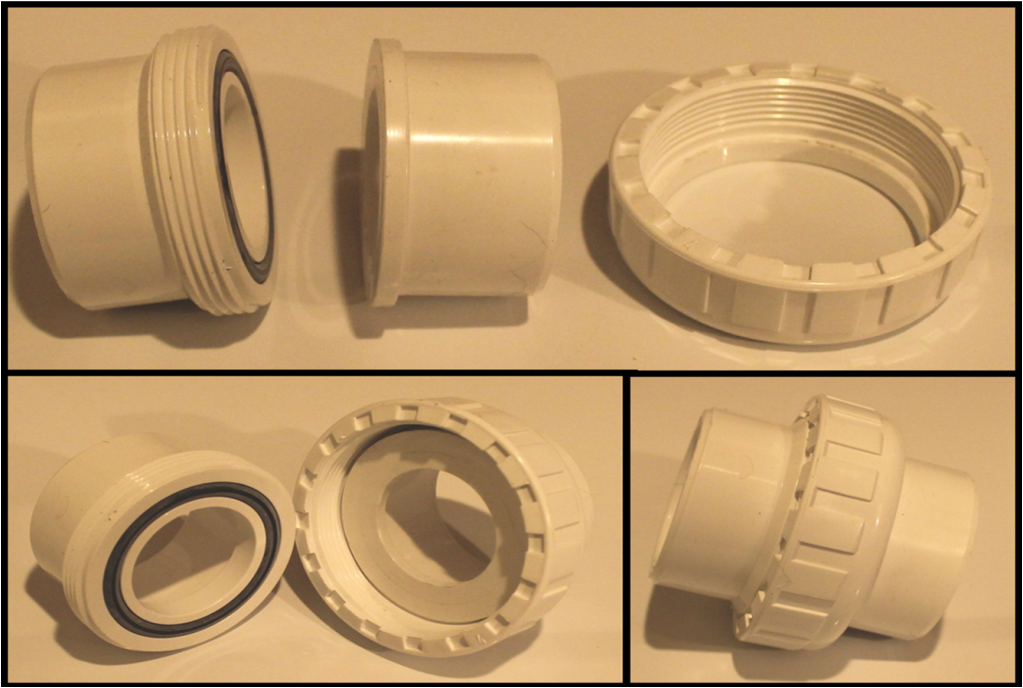

8) Unions-. These are type of couplings that are made of two halves with thread together. They allow you to quickly and easily disconnect a part of plumbing set-up and put it back together again. They also come in threaded and solvent combinations

Connecting fittings and pipe.

When using screwed fittings, it is always best to use a Teflon thread tape. This non-adhesive tape will fill in any potential gaps between the threads allowing the threaded connection to remain water tight and avoid any leaks. There are many different types of thread tape, each designed to be used with different types of materials and different applications. The most common type of thread tape that can be used in all the above listed materials will commonly be white in color and will be the most commonly found thread tape in just about any hardware store. This tape is also safe for aquarium use.

When using solvents to “glue” fittings and pipe together, please keep in mind there is a specific solvent designed to be used with each of the different material types listed above. Make sure to double check and ensure you are using the correct solvent for the type of material you are using. Using the wrong solvent can result in the joint developing a leak or even failing over time. Go ahead and check out this post to get informed on the best aquarium filters on the market.

As you may have noticed, all of the outside dimensions of the pipe listed about are all the same (as detailed in the applicable ASTM and CSA standards). If you choose to use combination of different material types you must ensure you are using the correct type of transition solvent designed to be used with both of types of materials. You can commonly find ABS/PVC DVW and PVC/CPVC transition solvents as well as a few other combinations. If you cannot find a transition solvent for both of the material types that you want to use, then you must assume you cannot use them together. When using two different material types, plan your set-up around the lower of the two specifications for the materials you are using.

Adapters. and Bushings.

Caps/plugs.

Couplings.

Elbows.

Tees

Flanges.

Unions

You can find a lot of other different plumbing products made of many different types of material, such as: Aqua-rise, Corzan PVC, Duraplas ABS, Aquatherm, and XFR PVC.Each of these have very specific uses which make them (in my opinion) not suitable for use in a sumped aquarium from a cost point of view.There are also companies that are starting to develop and market their own pipe products for use in the hobby.The below link shows an example of this.These manufactures state these products are PVC SCH 40 and can be used with regular PVC SCH 40 fittings.I cannot verify if these new products are in fact manufactured up to ASTM or CSA standards so I cannot validate the specifications these products are manufactured to.

http://reefbuilders.com/2013/08/19/pimp-aquarium-colored-pvc/